Nikola specializes in electricity transmission and control equipment installation works, providing comprehensive services to ensure reliable and efficient electrical infrastructure for industrial, commercial, and residential projects. With a focus on safety, quality, and innovation, we deliver tailored solutions that meet the specific needs of our clients.

Installing electricity transmission and control equipment involves a complex process to ensure the safe and efficient distribution of electrical power. Below is a detailed description of the installation works involved in electricity transmission and control equipment:

We have extensive experience in installing overhead and underground transmission lines for power distribution. Our team ensures the safe and efficient deployment of transmission infrastructure, adhering to industry standards and regulations.

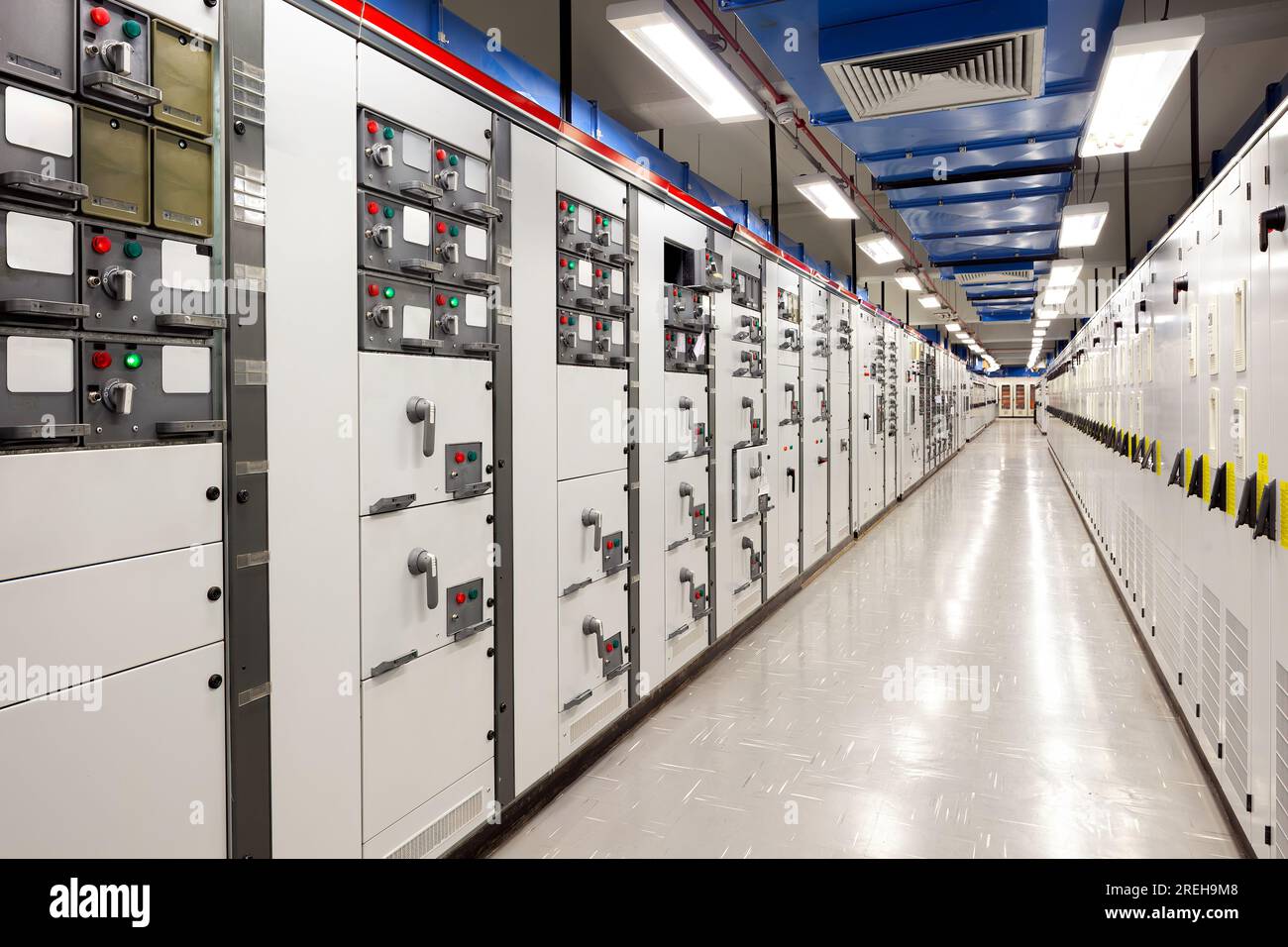

We design and build electrical substations for power distribution and control. Our services cover site preparation, equipment installation, commissioning, and testing to ensure optimal substation performance

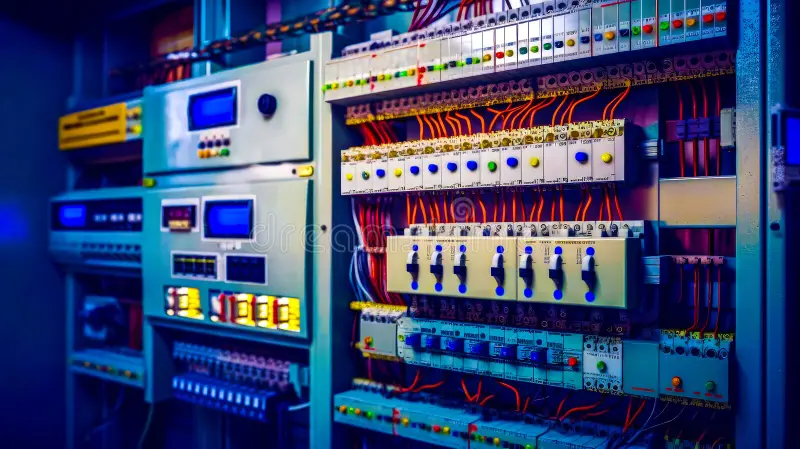

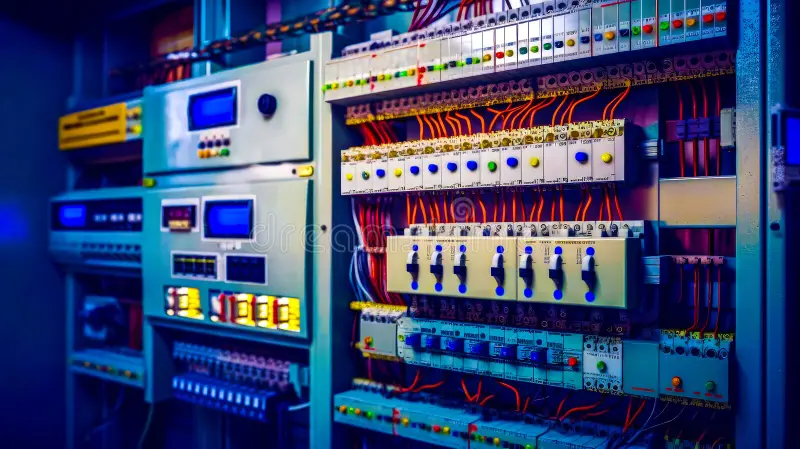

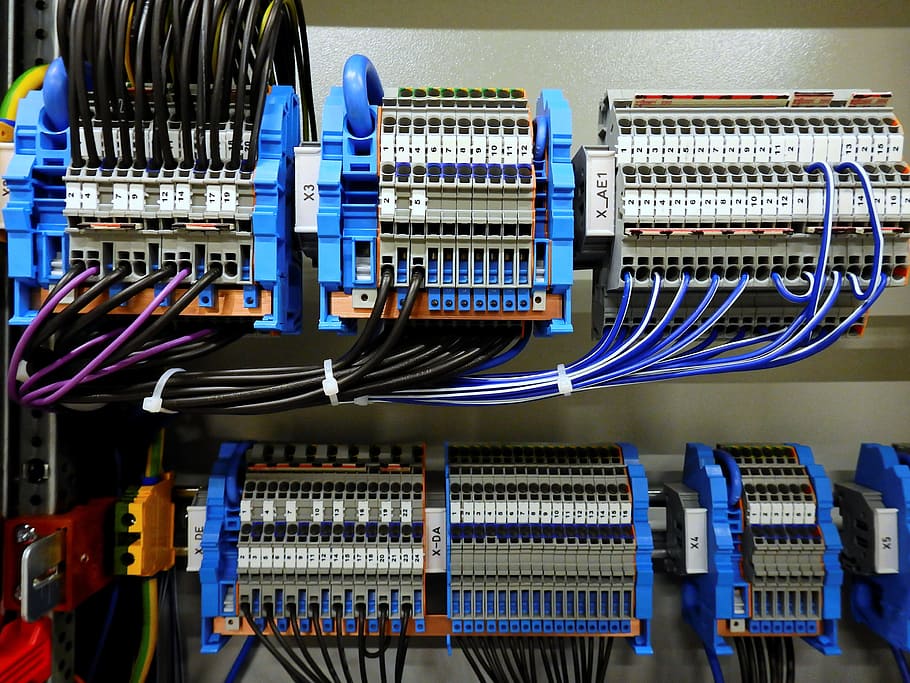

We install a wide range of control systems and equipment, including switchgear, transformers, relays, meters, and protective devices. Our expertise extends to complex control panel installations for industrial and commercial applications.

We design and deploy power distribution networks tailored to the needs of our clients. Whether it’s for a factory, office building, or residential complex, we ensure efficient and reliable electricity distribution within the premises.

Our solutions include automation systems and remote monitoring capabilities to enhance operational efficiency and enable remote management of electrical equipment and systems.

Safety is our top priority. We conduct rigorous testing, inspections, and compliance checks to ensure that all installed equipment meets safety standards and regulatory requirements.

Ans. 1. Ensure compliance with local regulations, codes, and safety standards.

2. Conduct site surveys to assess terrain, accessibility, and environmental factors.

3. Coordinate with utility companies for power grid connections.

4. Use proper equipment handling and lifting techniques for heavy components.

Ans. 1. Follow lockout/tagout procedures to de-energize equipment before work.

2. Use personal protective equipment (PPE) such as insulated gloves, safety goggles, and hard hats.

3.Implement proper grounding and isolation procedures to prevent electrical hazards.

4. Adhere to safe work practices when working at heights or in confined spaces.

Ans. Regular inspections and maintenance should be conducted according to industry standards and equipment specifications. This can range from monthly visual inspections to annual comprehensive checks.

Ans. Common issues include insulation degradation, mechanical wear, overheating, lightning strikes, and environmental factors (e.g., corrosion). Timely maintenance and periodic testing can help identify and address these issues.

Step into the future of technology with our innovative IT solutions

Copyright © 2024 NikolaMena | All Rights Reserved