Nikola is a leading provider of electromechanical equipment installation and maintenance services, offering comprehensive solutions to ensure the optimal performance and reliability of industrial, commercial, and residential systems. With a focus on efficiency, safety, and sustainability, we specialize in delivering customized services tailored to meet the unique needs of our clients.

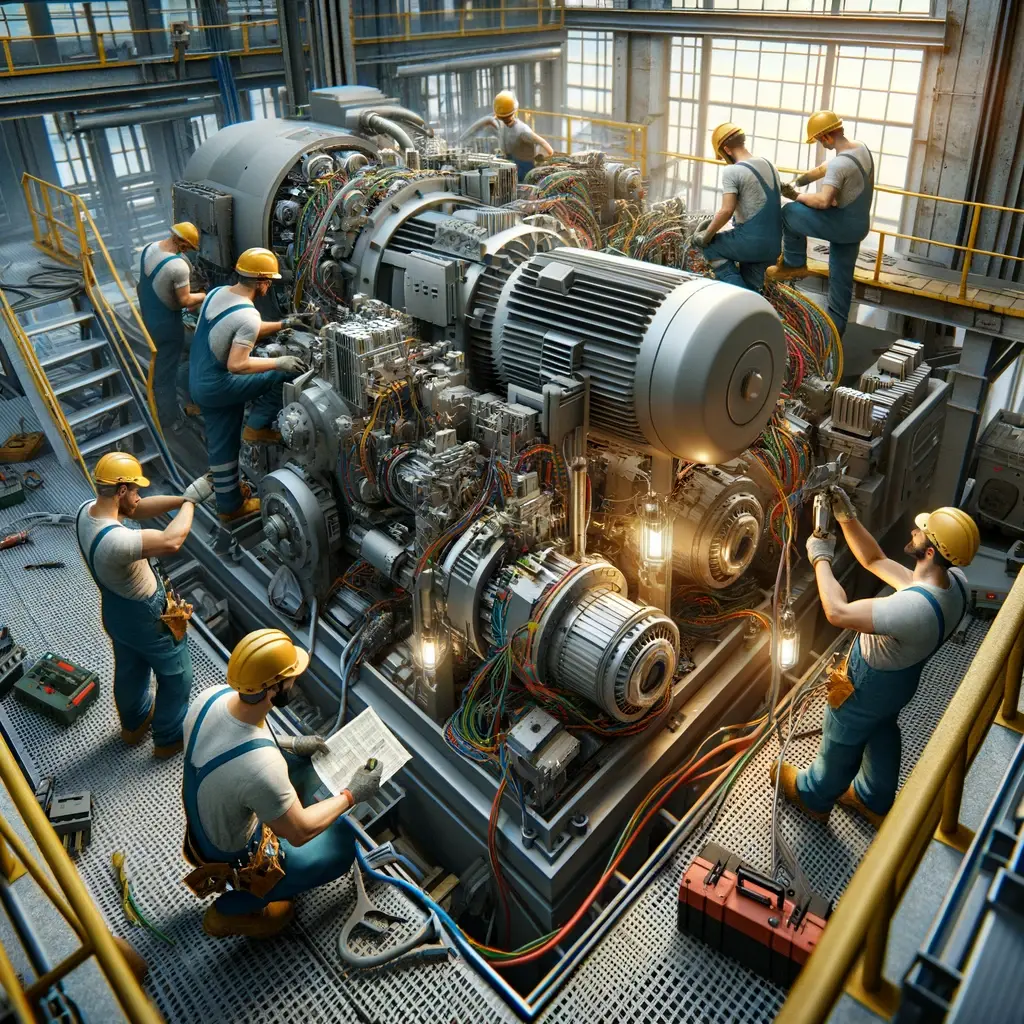

Electromechanical equipment installation and maintenance involves the setup, calibration, repair, and upkeep of machinery that combines electrical and mechanical components.

We specialize in the installation of various electromechanical systems, including HVAC (heating, ventilation, and air conditioning) systems, pumps, motors, generators, elevators, escalators, and other mechanical and electrical equipment

We provide proactive maintenance programs to prevent equipment breakdowns and optimize performance. Our maintenance services include regular inspections, lubrication, cleaning, and testing of electromechanical systems.

In the event of equipment failures or breakdowns, our rapid response team is available 24/7 to perform emergency repairs and restore functionality promptly. We understand the critical nature of electromechanical systems and aim to minimize downtime to keep operations running smoothly.

We offer upgrade and retrofit solutions to enhance the efficiency, reliability, and safety of existing electromechanical equipment. Whether it’s replacing outdated components, upgrading controls, or implementing energy-efficient technologies, we help optimize your systems for better performance and cost savings.

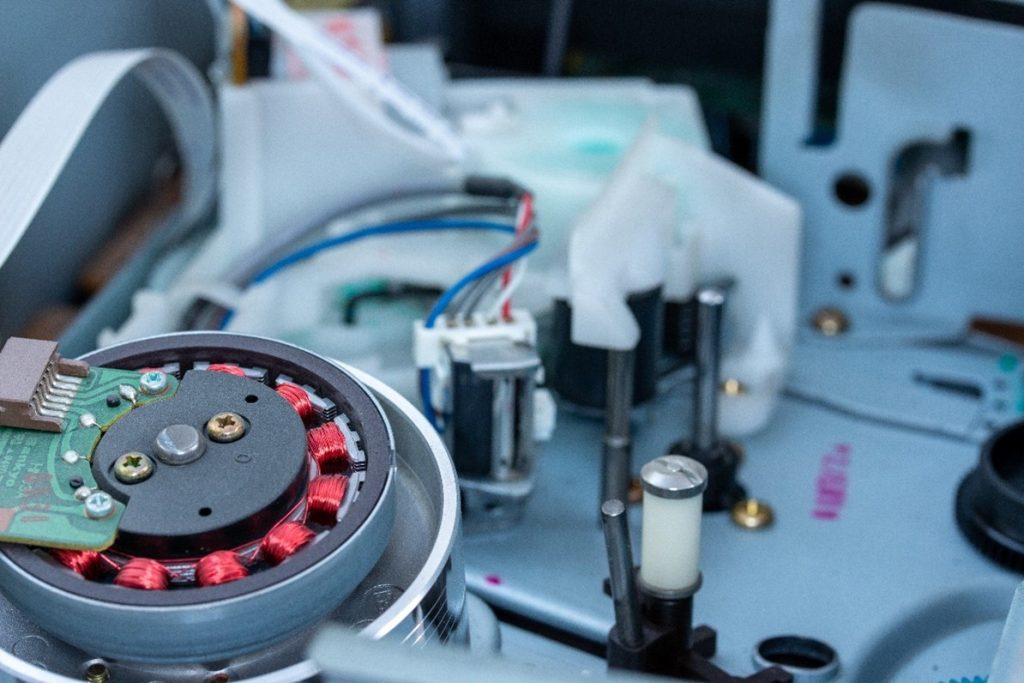

Our skilled technicians utilize advanced diagnostic tools and techniques to troubleshoot complex issues with electromechanical equipment. We identify root causes of problems and implement effective solutions to restore functionality and prevent recurring issues

We ensure that all installed equipment and systems comply with relevant safety regulations and industry standards. Our team conducts thorough safety inspections and compliance checks to mitigate risks and ensure a safe working environment.

Ans. 1. Ensure the equipment is compatible with existing electrical systems.

2. Follow manufacturer’s installation guidelines and specifications.

3. Properly size electrical components like wiring, breakers, and fuses.

4. Conduct safety assessments and comply with relevant codes and standards.

Ans. Regular inspections and maintenance should be conducted according to manufacturer recommendations and operational requirements. This typically ranges from monthly to annually depending on the type of equipment and usage intensity.

Ans. Common issues include motor overheating, bearing failures, electrical shorts, worn-out components, and control system malfunctions. Regular maintenance can help identify and address these issues early.

Ans. 1. Checking power supply and electrical connections.

2. Inspecting mechanical components for wear or damage.

3. Testing sensors, switches, and control systems.

4. Using diagnostic tools like multimeters or oscilloscopes.

5. Referencing equipment manuals and technical documentation.

Step into the future of technology with our innovative IT solutions

Copyright © 2024 NikolaMena | All Rights Reserved